DSI Internal Hex Implants

Blue Line Implant

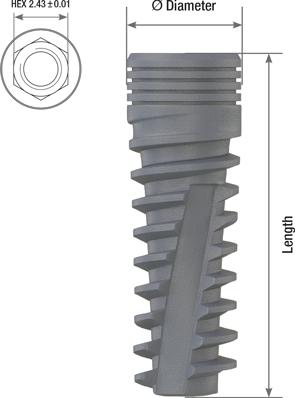

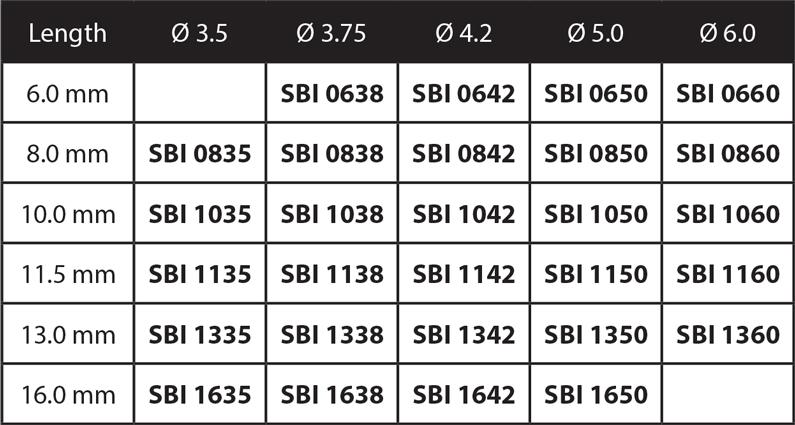

Immediate loading in a wide variety of cases of different bone types is possible thanks to the great stability of DSI Blue Line Spiral Implants which are designed with patented technology. DSI Blue Line iconic “aggressive” geometric shape includes dual threads, two spiral channels stemming from the apex, micro-grooves on the implant top and a changing thread thickness along with the implant. As a result, soft bone is collected and compressed during the implantation creating a strong and balanced platform ready for immediate loading. Platform switching preserves the crestal bone height and soft tissue levels, increasing the quality of outcomes in the treatments. One abutment platform fits all implant diameters. Packaging has been designed for quick identification and easy opening.

Each product undergoes the strictest quality control measures. We ensure that a high percentage of samples are taken from every batch. Each sample passes a very strict set of tests of cleanliness and conformity thus ensuring minimal rejections afterward. All of our products adhere to the highest international standards. All DSI Implants implants are made of titanium alloy Ti-6Al-4V ELI, in accordance with ASTM-F136-02. All DSI Blue Line implants undergo SLA surface treatment.

DSI Blue Line Implant Features:

• Aggressive, wide thread pitch, sharp and deep.

• Bone condensing property provides excellent primary stability.

• Special shape increases the implant’s external surface, accelerating the healing process.

• Ideally suited for multi-unit immediate load applications and insertion into fresh extraction sites.

• Platform switch design.

• Recommended for soft and mildly dense bones.

• Self-tapping capability.

• Two spiral channels stemming from the apex to adjust the implant integrity.

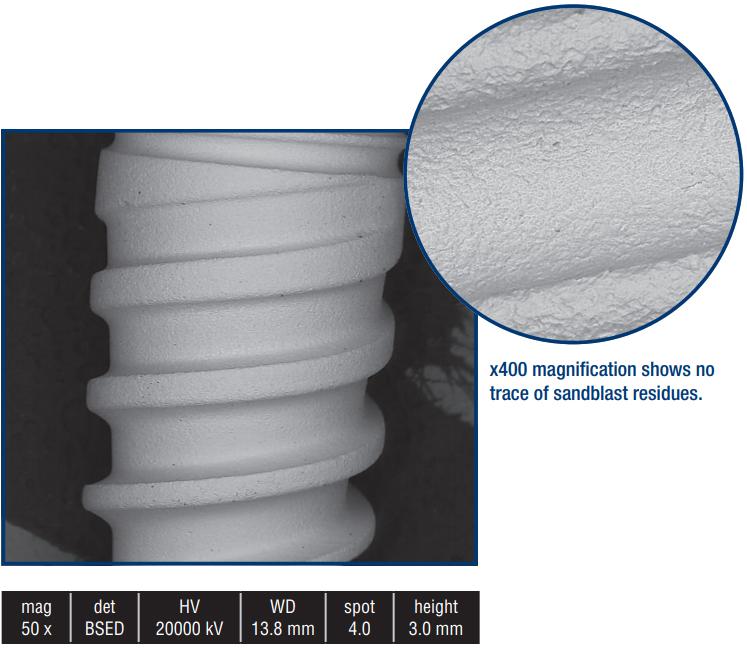

SLA Surface Treatment:

The classic SLA surface, short of «Sand-blast, Large grit, Acid-etch» is based on large aluminum oxide Al2O3 particles sandblasting technique that generates a macro-roughness on the titanium surface. Sandblasting is followed by acid-etching batch at high temperatures. As a result, subtle-sized 2-5 micron micropores appear at the implant surface. This unique macro/micro-topography provides an ideal structure for the cell attachment while reducing the possibility of bacterial colonization. SLA surface treatment technique seemed to be one of the most studied and best documented surfaced in a modern dental implantology. Cell culture tests, histological studies of bone, all confirmed its strong long-term performance, high mechanical stability and a low odds ratio of developing periimplantitis. This makes the SLA a perfect choice for the contact surfaces of the implants. DSI has improved the process, making it hands-free and minimizing the aluminum oxide residuals that may remain on the surface and could significantly impair osseointegration.

Survival rates:

• High and consistent survival rates (over 95% after a five-year follow-up).

Bone Preservation:

• Average bone loss of <1 mm after five years (Based on the implant loading time).

No Peri-Implantitis

• Very low prevalence of peri-implantitis over the 5-year follow-up period.

No aluminum contaminants

• Mean a more successful and accelerated process of osseointegration than ever.

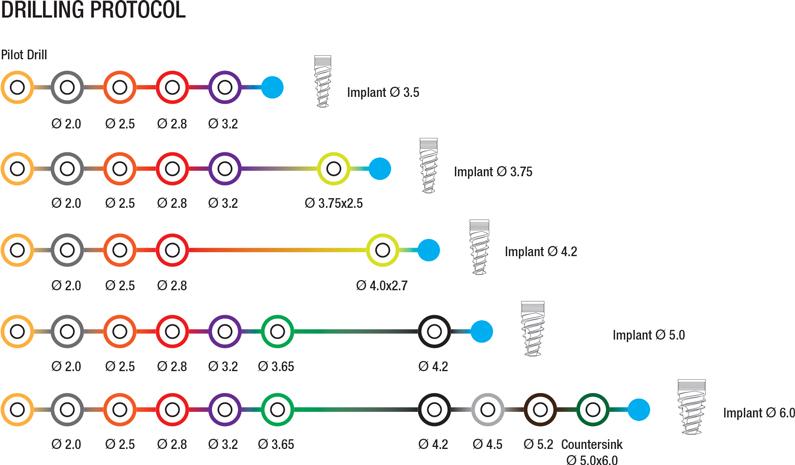

DSI Blue line implant drilling protocol: