DSI Internal Hex ImplantsSmart Implant

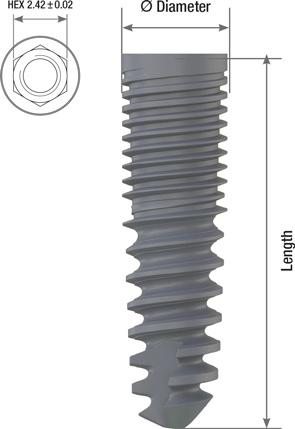

As the popularity of dental implants in restorative procedures rises, there is a need to find innovative solutions, which can effectively transfer the loads and provide the necessary stabilization into the jawbone. DSI Smart implant was designed by careful histological analysis of the different qualities of the bone at its cortical and spongiosal parts, to ensure a reduction of drilling volume along with an additional gain of primary stabilization. The lower part, slightly tapered, is consisted of 0.9mm deep thread and a wide tread in order to allow better grip at the spongiosal bone through its compression while enabling high blood supply around the core of the implant. This high blood supply is crucial for the bio-activity of the bone. The second thread overlaps with the first and ends after 5.5mm from the top. The advancement of these two threads is identical on the upper and lower parts so that the implant advances at an equal pace through its entire length. This eliminates any tension between the upper and lower part of the implant. The design of the groove at the apex of the implant enables the implant to cut through the bone and compress it towards the implant’s core. Hybrid Dual Thread Screw approach allows obtaining a high reinforcement of the implant in the jawbone by a reduction of the drilling bone volume along with the additional gain of primary surface contact.

HDTS – Hybrid Dual Thread Screw – Implants:

The unique HDTS dental Implant uses two different thread types, double thread-thin grove at the implant interface area with the cortical bone, and a single thread thick groves at the cancellous bone. This special design promotes the transfer of occlusal forces to the greatest surface area of the bone-implant interface for favorable load distribution. Also, it diminishes the amount of bone removed by using a novel drilling procedure.

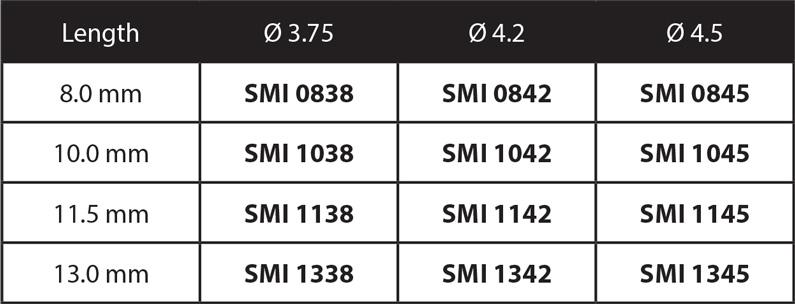

DSI’s SMART dual thread implants have a varying screw width. The implant is an internal hex and uses a universal 3.75mm platform for all diameters above 3mm. The implant consists of one screw width along with the entire implant – the upper part’s thread starts at 0.2mm depth and gradually expands to 0.9mm after 5.5mm from the top. The correlation between the implant’s shape and the bone type to which it enters results in an equal distribution of load forces along the entire length of the implant, and increased primary stability of the implant. All DSI SMART implants undergo SLA surface treatment.

DSI SMART Implant Features:

• Hybrid Dual Thread Screw designed to better grasp at the cortical bone without compressing it.

• Superb spongiosal bone grip.

• Equal distribution of load forces along the entire length of the implant.

• Withstands higher axial & vertical loads compared to other implants.

• Enabling high blood supply around the core of the implant.

• Maximum primary stability.

• Ideally suited for both immediate loading and traditional 2-stage protocols.

• Rounded apex with self-tapping threads for optimal surgical flexibility.

• Internal hex connection accepts the full range of the DSI Prosthetic components.

• DSI Implants implants are made of titanium alloy Ti-6Al-4V ELI, in accordance with ASTM-F136-02.

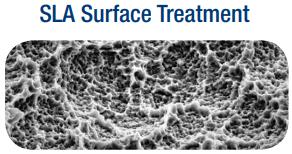

SLA Surface Treatment:

The classic SLA surface, short of «Sand-blast, Large grit, Acid-etch» is based on large aluminum oxide Al2O3 particles sandblasting technique that generates a macro-roughness on the titanium surface. Sandblasting is followed by acid-etching batch at high temperatures. As a result, subtle-sized 2-5 micron micropores appear at the implant surface. This unique macro/micro-topography provides an ideal structure for the cell attachment while reducing the possibility of bacterial colonization. SLA surface treatment technique seemed to be one of the most studied and best documented surfaced in a modern dental implantology. Cell culture tests, histological studies of bone, all confirmed its strong long-term performance, high mechanical stability and a low odds ratio of developing periimplantitis. This makes the SLA a perfect choice for the contact surfaces of the implants. DSI has improved the process, making it hands-free and minimizing the aluminum oxide residuals that may remain on the surface and could significantly impair osseointegration.

Survival rates:

• High and consistent survival rates (over 95% after a five-year follow-up).

Bone Preservation:

• Average bone loss of <1 mm after five years (Based on the implant loading time).

No Peri-Implantitis

• Very low prevalence of peri-implantitis over the 5-year follow-up period.

No aluminum contaminants

• Mean a more successful and accelerated process of osseointegration than ever.

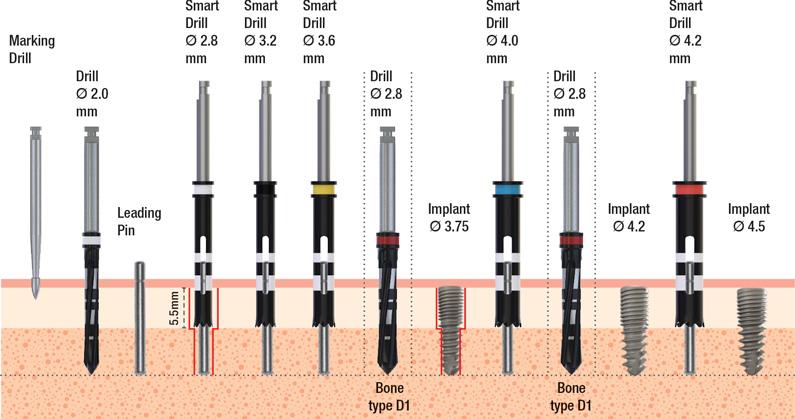

DSI SMART Implant Drilling Protocol: